Revolutionizing Manufacturing: The Power of 3D Printing

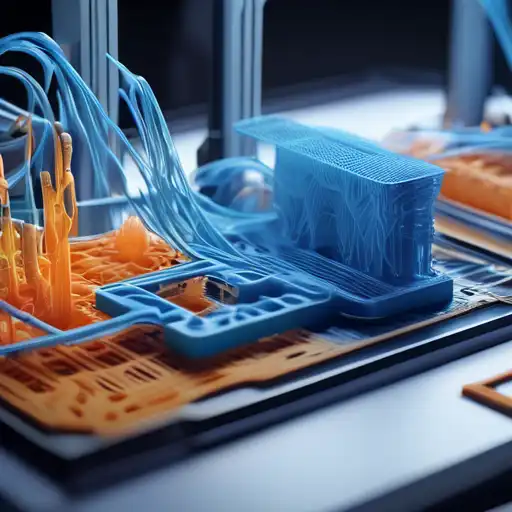

3D printing, also known as additive manufacturing, is transforming the way we create objects, from simple household items to complex industrial components. This groundbreaking technology builds objects layer by layer, offering unparalleled flexibility and efficiency in production processes.

The Basics of 3D Printing

At its core, 3D printing involves creating a three-dimensional object from a digital file. The process starts with designing a model using computer-aided design (CAD) software. This model is then sliced into thin layers by specialized software, which the 3D printer reads to construct the object layer by layer.

Applications of 3D Printing

The applications of 3D printing are vast and varied, spanning across industries such as healthcare, automotive, aerospace, and fashion. In healthcare, for example, 3D printing is used to create custom prosthetics and even bioprint tissues. The automotive industry utilizes 3D printing for prototyping and manufacturing parts, reducing both time and costs.

- Healthcare: Custom prosthetics, dental implants, and bioprinting.

- Automotive: Prototyping, custom parts, and tooling.

- Aerospace: Lightweight components and complex geometries.

- Fashion: Custom jewelry and avant-garde clothing.

The Future of 3D Printing

As 3D printing technology continues to evolve, its potential seems limitless. Innovations such as faster printing speeds, new materials, and larger build volumes are making 3D printing more accessible and practical for a wider range of applications. The future may see 3D printing playing a pivotal role in sustainable manufacturing, with the ability to recycle materials and reduce waste.

Moreover, the integration of AI and 3D printing is opening new frontiers, enabling smarter design processes and more efficient production methods. This synergy between technologies is set to redefine manufacturing and design in the years to come.

Challenges and Considerations

Despite its many benefits, 3D printing faces challenges such as material limitations, high costs for industrial-grade printers, and intellectual property concerns. However, ongoing research and development are addressing these issues, paving the way for broader adoption.

For those interested in exploring 3D printing, starting with a small, affordable printer and experimenting with different materials and designs can be a great way to understand the technology's potential. Resources like 3D printing tutorials can provide valuable guidance for beginners.

In conclusion, 3D printing is not just a tool for creating objects; it's a revolutionary technology that's reshaping industries and empowering creators. By building the future layer by layer, 3D printing is unlocking new possibilities in manufacturing, design, and beyond.